1. Product Description

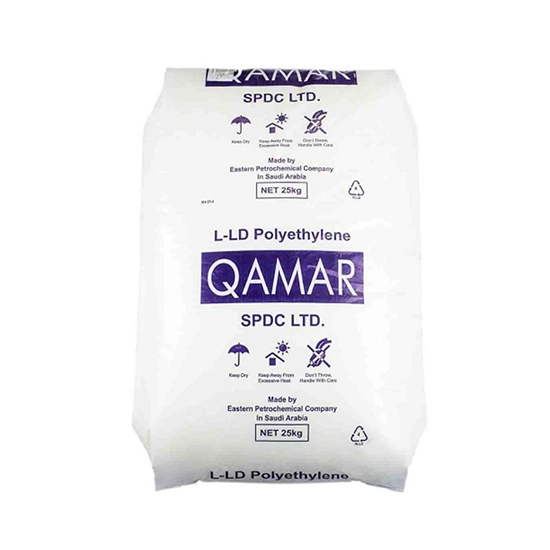

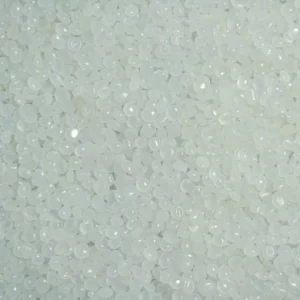

Virgin Resin – LLDPE FD21HS is a high-performance ethylene-butene copolymer produced by Sharq Petrochemical Company (SPDC) under the QAMAR brand (Saudi Arabia). Known for its superior flexibility and versatility, this grade is specifically engineered for both blown film and extrusion processes.

The resin is pre-integrated with high-quality Slip and Antiblocking additives, which optimize the production flow by reducing friction and preventing film sticking, ensuring a seamless manufacturing experience.

- Density: ~0.918 g/cm³

- Melt Index (MI): ~2.0 g/10 min (190 °C/2.16 kg)

- Primary Applications: Blown film, cast film, agricultural mulch, and various consumer packaging.

2. Typical Technical Specifications

> Note: These values are typical properties provided for reference only and do not constitute a formal product specification. Please refer to the manufacturer’s TDS for official limits.

3. Advantages & Disadvantages

Advantages:

- 100% Virgin Material: Ensures consistent quality, superior physical strength, and excellent optical clarity for end-products.

- High Processing Speed: The molecular structure is optimized for rapid blown film and cast extrusion, significantly boosting factory output.

- Integrated Performance Additives: Pre-mixed with slip and antiblock agents to minimize surface friction and eliminate “film-to-film” adhesion issues.

- Outstanding Toughness: Delivers high elongation and impact resistance, making it perfect for functional packaging and heavy-duty use.

Disadvantages:

- Premium Cost: As a high-grade virgin resin, the price point is typically higher than recycled or off-grade alternatives.

- Over-Specification: For applications with minimal technical requirements, FD21HS might exceed necessary standards, potentially leading to non-optimized material costs.

- Technical Precision Required: Requires proper machinery calibration and temperature control; incorrect settings may lead to thickness variations or surface defects.

4. Main Applications

Virgin Resin – LLDPE FD21HS is the ideal solution for:

- Blown Film: Shopping bags, light-to-medium duty packaging, and produce bags.

- Cast & Extrusion Film: Protective lamination films, food wraps, and high-quality agricultural films.

- Consumer Packaging: Zipper bags, pouch films, household liners, and food-grade packaging (subject to certification).

- High-End Industrial Use: Applications demanding a perfect balance of transparency, toughness, and production efficiency.

5. Selection & Usage Guidelines

- Process Compatibility: Confirm the appropriate grade based on your production method (Blown vs. Cast) and target film thickness.

- Machinery Setup: For blown film, a Blow-Up Ratio (BUR) between 2.0 – 4.0 is highly recommended.

- Thermal Management: Ensure precise melt temperature control, typically around 180 °C for optimal flow and stability.

- Proper Storage: Store in a cool, dry environment. Avoid moisture and direct UV exposure to maintain the effectiveness of the additives and resin integrity.

- Regulatory Verification: For specialized applications like food-contact packaging, verify compliance with regional and international standards (FDA, EU) through the official manufacturer certificates.

Reviews

There are no reviews yet.