1. Product Description

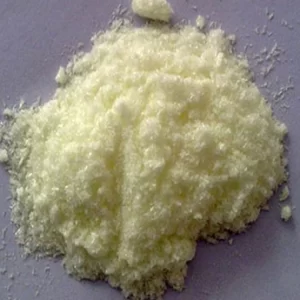

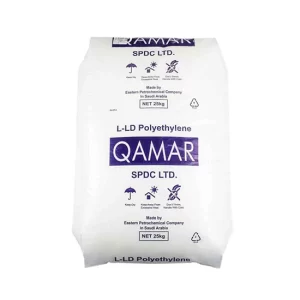

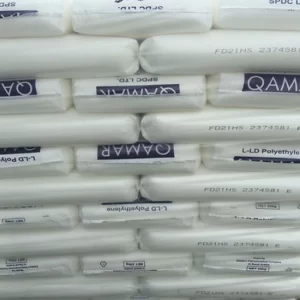

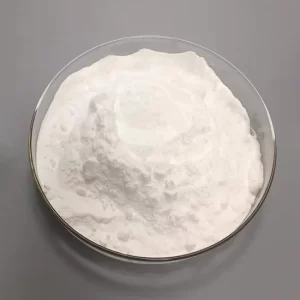

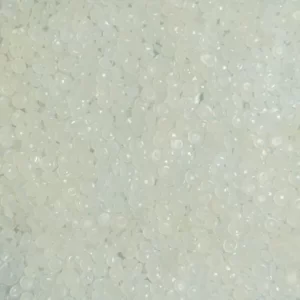

Virgin Resin – LLDPE 218WJ is a premium Linear Low-Density Polyethylene (LLDPE) manufactured by SABIC. It is a butene copolymer (C4) grade produced using advanced technology, ensuring a TNPP-free composition for enhanced safety in general-purpose packaging applications.

This grade is specifically engineered to provide an excellent balance of processability, mechanical strength, and optical properties. It comes pre-integrated with Slip and Antiblocking additives to optimize production efficiency and surface performance.

- Melt Flow Rate (MFR): ~2.0 g/10 min (190 °C/2.16 kg).

- Density: ~0.918 g/cm³ (ASTM D1505).

- Primary Processes: Blown film, lamination, and general extrusion.

2. Typical Technical Specifications

> Note: These are typical values and should not be construed as specifications. Users are encouraged to refer to the official Technical Data Sheet (TDS) for precise limits.

3. Advantages & Disadvantages

Advantages:

- 100% Virgin Quality: Ensures maximum purity, consistency, and stability compared to recycled or blended resins.

- Excellent Mechanical & Optical Balance: High toughness and elongation coupled with good clarity, ideal for thin-film applications.

- Integrated Additives: Pre-mixed with slip and antiblock agents to reduce coefficient of friction (COF), preventing film sticking and boosting production speed.

- Safety Standards: TNPP-free formulation, suitable for consumer-grade and food-contact packaging applications.

Disadvantages:

- Premium Pricing: Higher cost compared to recycled resins or off-grade blends.

- Storage Sensitivity: Requires strict storage conditions to prevent degradation from UV light, high temperatures, or humidity.

4. Main Applications

Virgin Resin – LLDPE 218WJ is highly versatile and widely used for:

- Blown Film: High-quality thin films, grocery bags, and T-shirt bags.

- Packaging: Food-grade liners, frozen food bags, and heavy-duty sacks.

- Lamination & Co-extrusion: Ideal as a sealing or core layer in multi-layer film structures.

- Consumer Goods: Garment bags, shopping bags, and general-purpose plastic liners requiring high elongation and tear resistance.

5. Guidelines for Usage & Selection

- Application Assessment: Evaluate end-product requirements for elongation, tensile strength, and optical haze. LLDPE 218WJ is ideal for films needing high stretchability.

- Processing Conditions: For optimal results, SABIC recommends a melt temperature of 185–205 °C and a Blow-Up Ratio (BUR) of 2.0–3.0.

- Machinery Calibration: Adjust line speeds and tension controls to accommodate the high elongation properties of the 218WJ grade to prevent gauge instability.

- Proper Storage: Keep in a dry, cool area (below 50 °C). Avoid direct sunlight and moisture to ensure the additives perform consistently and the resin does not degrade.

Reviews

There are no reviews yet.