(UV Absorber – 2-Hydroxy-4-n-octoxybenzophenone, CAS No. 1843-05-6)

1. Product Description

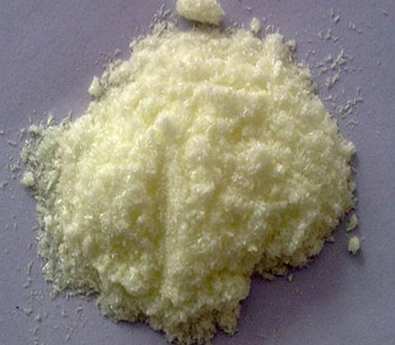

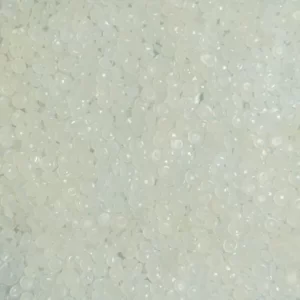

UV Stabilizer UVA 531, also known as UV 531, is a benzophenone-type ultraviolet light absorber. Its chemical name is 2-Hydroxy-4-n-octoxybenzophenone.

- CAS No.: 1843-05-6.

- Molecular Formula: C₁₉H₂₂O₃ (Molecular weight approx. 326 g/mol).

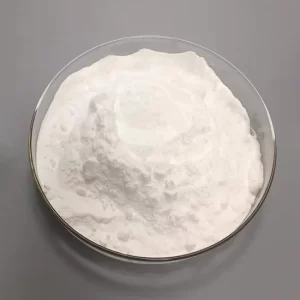

- Physical Form: Typically appears as a pale yellow crystalline powder or in granular/flake forms.

UV 531 is engineered to absorb and convert ultraviolet (UV) energy into heat or less harmful forms, thereby protecting polymers from degradation, discoloration, or surface embrittlement.

2. Key Features

- Broad-Spectrum UV Absorption: Effectively absorbs UV rays in the range of approximately 270-340 nm — ideal for protecting outdoor plastic applications.

- Broad Compatibility: Excellent compatibility with various polymers including PE, HDPE, LDPE, PP, PVC, PS, PC, EVA, etc.

- Low Color Contribution: Its light color ensures minimal impact on the final product’s appearance, preserving clarity and transparency.

- High Thermal Stability: Suitable for high-temperature processing with low volatility and resistance to migration within the plastic matrix.

- Extended Service Life: Proactively prevents the loss of mechanical properties, color fading, or surface cracking in outdoor plastic products.

3. Applications

UVA 531 is widely utilized in various sectors, including:

- Agriculture & Packaging: Outdoor packaging films, agricultural films (LDPE/LLDPE, EVA).

- Infrastructure: Plastic pipes, cables, and outdoor housings made from PE, HDPE, and PVC.

- Industrial & Engineering Plastics: Injection-molded parts, technical components, and outdoor furniture (e.g., plastic chairs, electrical housings, automotive parts).

- Coatings & Inks: Outdoor paints, coatings, and inks where color stability and weatherability are critical.

- Synergistic Formulations: Often combined with HALS (Hindered Amine Light Stabilizers) to maximize UV protection in polyolefin systems.

4. Guidelines for Selection & Usage

Selection:

- Identify the base resin type and application conditions (indoor vs. outdoor, heat requirements, intensity of light exposure).

- Follow the recommended dosage: typically ranges from 0.1% to 0.5% by weight of the polymer, depending on the resin type and performance requirements.

- Combine with compatible additives like HALS if enhanced protection is needed.

Usage:

- Incorporate UV 531 into the resin or masterbatch before processing, ensuring uniform dispersion.

- Ensure processing equipment and temperatures are calibrated to prevent thermal degradation of the additive.

- Storage: Store in a dry environment, away from direct sunlight and high temperatures, to maintain optimal additive performance.

Reviews

There are no reviews yet.