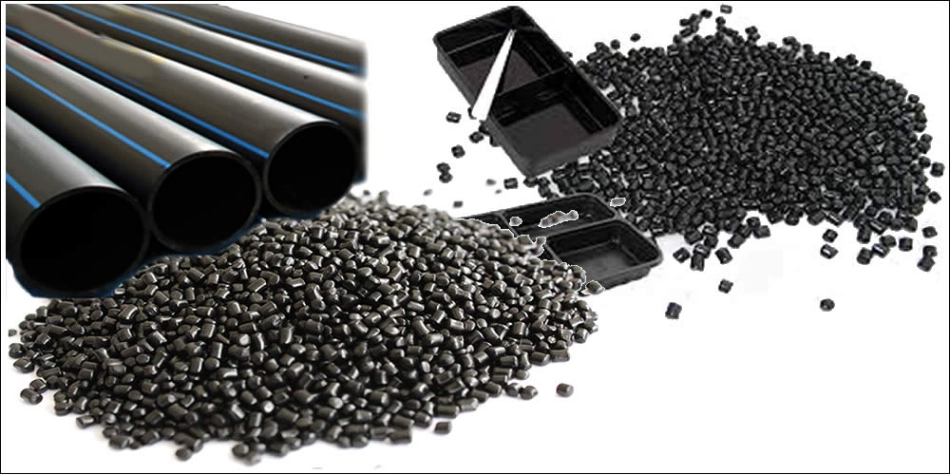

1. Product Description

Black Masterbatch is a pre-mixed plastic additive consisting of high-quality carbon black pigments, a carrier resin, and specialized additives. When mixed with base resins (such as PP, PE, PS, etc.), Black Masterbatch ensures the final product achieves a deep, uniform black color with stable properties. Additionally, it enhances UV resistance, thermal stability, and improves other physical characteristics of the plastic.

2. Key Features

- Deep and Uniform Black: High carbon black content delivers superior “jetness” – providing a deep and sharp black shade.

- Excellent Dispersion: The pre-formulated carrier resin ensures more uniform dispersion compared to using raw pigment powder.

- Thermal and UV Stability: Ideal for outdoor applications or products exposed to sunlight, preventing fading and rapid aging.

- Cost-Efficiency & Production Optimization: Reduces material loss, minimizes dust, and allows for easier color control compared to traditional methods.

- Broad Compatibility: Suitable for various processing methods, including injection molding, extrusion, and film blowing.

3. Applications

Black Masterbatch is widely used across the plastics industry, including:

- Automotive & Engineering Components: Car shells, bumpers, interior/exterior parts, and mechanical tools.

- Packaging & Plastic Films: Shopping bags, garbage bags, protective films, and agricultural mulch films.

- Pipes, Sheets, and Construction Profiles: Products requiring consistent color and weather resistance.

- Outdoor Materials & Geotextiles: Benefiting from enhanced UV protection and anti-aging properties.

4. Selection & Usage Guidelines

To choose the right Black Masterbatch, consider the following:

- Base Resin Compatibility: Ensure the masterbatch carrier is compatible with your base material (PP, PE, PS, PVC, etc.).

- Environmental Exposure: For outdoor use, select variants with UV stabilizers and anti-aging additives.

- Opacity & Carbon Black Content: Higher concentrations are required for better coverage and deeper “jetness.”

- Processing Conditions: The masterbatch must withstand the specific temperatures and pressures of your production process (extrusion, molding, etc.).

- Let-down Ratio: Always consult with the supplier for the recommended mixing ratio and conduct sample trials.

5. Why Choose Our Product?

- Premium Quality: High dispersion, deep black color, and consistent physical properties.

- Versatile Compatibility: Supports a wide range of resins (PP/PE/PS) and processing technologies.

- Technical Support: We provide expert consulting, color matching services, and cost optimization.

- Standardized Packaging: Ensures the product remains moisture-free and maintains its integrity until use.

Reviews

There are no reviews yet.